Volvo announces self-made batteries and CTC technology

From the perspective of Volvo’s strategy, it is accelerating the transformation of electrification and is actively developing CTP and CTC technologies to build a diversified battery supply system.

The battery supply crisis under the global electrification wave has intensified, forcing more and more OEMs to join the camp of self-made batteries.

On June 30, Volvo Cars Group released Volvo Cars Tech Moment to share Volvo’s future electric vehicle technology development roadmap. The goal is to achieve full electrification by 2030.

At the event, Volvo revealed a lot of information about power battery technology, including second-generation PACK technology, next-generation CTC solutions, and self-produced batteries.

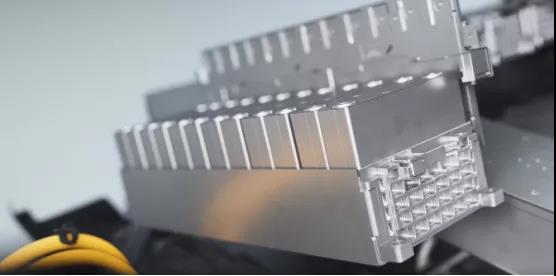

Among them, Volvo’s second-generation pure electric vehicle will start with the upcoming new all-electric Volvo XC90, which uses Volvo’s second-generation power battery PACK technology, 590 module technology, and square batteries.

It is reported that Volvo’s high-end electric brand Polestar’s first pure electric SUV model Polestar 3 will also use this battery technology, which is expected to be produced in South Carolina in the United States in 2022.

In terms of third-generation electric vehicle products, Volvo hinted that the battery pack of its third-generation battery system integration technology will become an indispensable part of the car’s structure, which means that it may be a CTC solution to achieve higher energy density (1000 Wh/L) and longer battery life (1000km).

This technology is similar to the plans of Tesla, Volkswagen, CATL and other companies. The route is to further reduce unnecessary structures at the module level, integrate the battery cell and the chassis, and then integrate the motor, electronic control, and vehicle high voltage such as DC /DC, OBC, etc. are integrated through an innovative architecture.

Similar to CTP technology, CTC technology can minimize the weight of the battery pack and increase the internal utilization space, and improve the efficiency of battery integration, thereby increasing the system energy density and vehicle mileage.

From the perspective of the technical route, Volvo’s third-generation PACK technology also uses square cells.

In order to achieve its electrification goals, Volvo is actively constructing its battery supply system.

Foreign media reported that Volvo Cars and Northvolt announced the establishment of a power battery joint venture to jointly develop and produce power batteries to supply power batteries for Volvo and Polestar’s next-generation pure electric vehicles.

The two parties will first establish a research and development center in Sweden, and will start operations in 2022; and build a large battery factory in Europe, with a capacity of 15GWh by 2024 and 50GWh by 2026.

This means that self-produced batteries may become the main source of Volvo’s later electric vehicle battery supply.

At the same time, Volvo also plans to purchase 15 GWh of power batteries from Northvolt’s Northvolt Ett plant in Skellefteå, Sweden, starting from 2024.

From the perspective of Volvo’s strategy, it is accelerating its electrification transformation, and is actively developing CTP and CTC technologies to build a diversified battery supply system.

At present, Volvo has reached cooperation with LG New Energy, CATL and Northvolt, and it is expected that new battery suppliers will be introduced in the later period.

Post time: Jul-03-2021